Direct-to-Film (DTF) transfer is a printing technique for directly applying images to film surfaces, offering high quality and durability. Optimal print quality depends on considering design size, resolution, and substrate choice. Larger prints are suitable for detailed designs but may have longer drying times, while smaller ones are faster but simpler. Substrates like PVC, acrylic, and vinyl provide different qualities crucial for aesthetic and functional requirements. Color accuracy is enhanced through color management systems and advanced image editing software. For complex DTF orders, breaking down designs into components and using specialized software ensures success.

“In the realm of printing, Direct-to-Film (DTF) transfer has emerged as a game-changer, offering unparalleled versatility and quality. This article explores the diverse dimensional options available for direct-to-film transfer orders, catering to various needs from vibrant, bustling designs to complex labyrinthine patterns. Understanding DTF’s intricacies, from material choices to techniques enhancing color accuracy, is key to successful navigation of this powerful printing method. Dive into these insights to optimize your DTF prints.”

- Understanding Direct-to-Film (DTF) Transfer: A Basic Overview

- Dimensional Considerations for DTF Transfer Orders

- The Impact of Print Size on DTF Printing Quality

- Material Choices: Substrates for Optimal DTF Prints

- Techniques to Enhance Color Accuracy in DTF Transfers

- Navigating Complex Designs: Strategies for DTF Transfer Success

Understanding Direct-to-Film (DTF) Transfer: A Basic Overview

Direct-to-Film (DTF) transfer is a cutting-edge printing technique that offers exciting dimensional options for various applications, especially in film and photography. This process eliminates the need for intermediate steps, allowing for direct application of an image or design onto a film surface. DTF Printing involves using specialized equipment to precisely deposit ink onto the desired medium, resulting in high-quality, durable prints.

The beauty of DTF lies in its versatility; it can be employed for both indoor and outdoor use, making it suitable for short-term or long-lasting displays. Whether adorning walls with vibrant murals, creating eye-catching window graphics, or producing pop-up signs, DTF Transfer offers a swift and efficient solution. Its direct application method ensures that colors remain rich and vibrant, while the film’s durability provides resistance to fading and wear, making it an ideal choice for both residential and commercial projects.

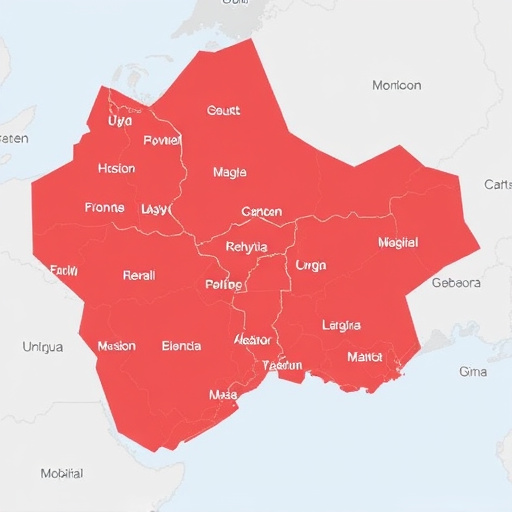

Dimensional Considerations for DTF Transfer Orders

When placing a direct-to-film (DTF) transfer order, dimensional considerations are crucial to ensure optimal print quality and efficient production. The size and resolution of the design play a significant role in determining the final output. For DTF transfers, it’s essential to take into account the physical dimensions of the substrate, including its length, width, and thickness.

Choosing the right dimensions for your DTF prints involves understanding the capabilities of the printing process. Different substrates have varying maximum print areas, so designing with these constraints in mind is vital. Additionally, the desired detail level of the final image or artwork should align with the resolution achievable through DTF printing. This ensures that fine details are not lost and the overall visual impact remains intact.

The Impact of Print Size on DTF Printing Quality

The print size plays a pivotal role in determining the quality of Direct-to-Film (DTF) transfer orders. In DTF printing, the larger the print area, the more intricate and detailed the design can be. This is because wider prints allow for better resolution, resulting in crisp, high-quality images on the final product. However, it’s important to note that excessively large prints may also introduce challenges, such as potential misalignment during the transfer process and longer drying times, which could impact overall efficiency.

For optimal DTF printing results, finding the right balance between print size and design complexity is key. Smaller DTF transfers are ideal for simple, text-based designs or logos, ensuring quick production times without compromising on clarity. Conversely, larger prints are suitable for more intricate artwork, photos, or illustrations, allowing for a vibrant and detailed final output.

Material Choices: Substrates for Optimal DTF Prints

When it comes to direct-to-film (DTF) transfer orders, the choice of material or substrate is paramount for achieving optimal print results. The substrate serves as the canvas for your design, and its properties directly influence the final quality of DTF prints. Different materials offer unique characteristics, from durability and opacity to texture and color absorption, each playing a role in enhancing or hindering the printing process.

For high-quality DTF prints, selecting the right substrate is crucial. Common options include polyvinyl chloride (PVC), acrylic, and vinyl. PVC is popular for its clarity and durability, making it suitable for detailed designs and outdoor applications. Acrylic sheets provide a glossy finish and superior impact resistance, ideal for creating vibrant, long-lasting prints. Vinyl, versatile and cost-effective, offers good opacity and can be easily cut and processed, making it a favorite among many DTF printers. Each material has its strengths, catering to various printing needs, whether for signage, decorations, or promotional items, ensuring that the final DTF transfer meets the desired aesthetic and functional requirements.

Techniques to Enhance Color Accuracy in DTF Transfers

Enhancing color accuracy in direct-to-film (DTF) transfer orders is paramount to achieving exceptional print quality. One effective technique involves utilizing advanced color management systems that calibrate and profile each DTF printer, ensuring consistent color output across different media types. This process involves capturing and storing the unique characteristics of each printer’s color reproduction, allowing for precise adjustments during the transfer stage.

Additionally, leveraging high-resolution input images with wide color gamuts and employing sophisticated image editing software can significantly improve results. By fine-tuning colors, contrast, and brightness levels before sending the file to print, DTF specialists can create vivid and accurate representations of the original artwork. These meticulous techniques, combined with state-of-the-art printing technology, result in stunning DTF prints, ensuring that every detail is preserved across various dimensions.

Navigating Complex Designs: Strategies for DTF Transfer Success

Navigating Complex Designs: Strategies for DTF Transfer Success

When it comes to direct-to-film (DTF) transfer orders, intricate and complex designs pose unique challenges. The success of a DTF print heavily relies on the ability to translate detailed artwork accurately onto the desired surface. One key strategy is breaking down complex designs into manageable components. By segmenting the image, printers can focus on individual elements, ensuring each part aligns perfectly during the transfer process. This meticulous approach, coupled with high-resolution digital files, allows for intricate details to be captured without compromise.

Additionally, utilizing specialized software designed for DTF printing offers significant advantages. These tools provide precise control over settings like exposure time and mask generation, enabling printers to tailor the transfer process to specific design requirements. Regular calibration of equipment and consistent use of high-quality film and inks further contribute to achieving optimal results, ensuring that complex designs are reproduced with exceptional accuracy and detail in DTF prints.